Composite autoclaves

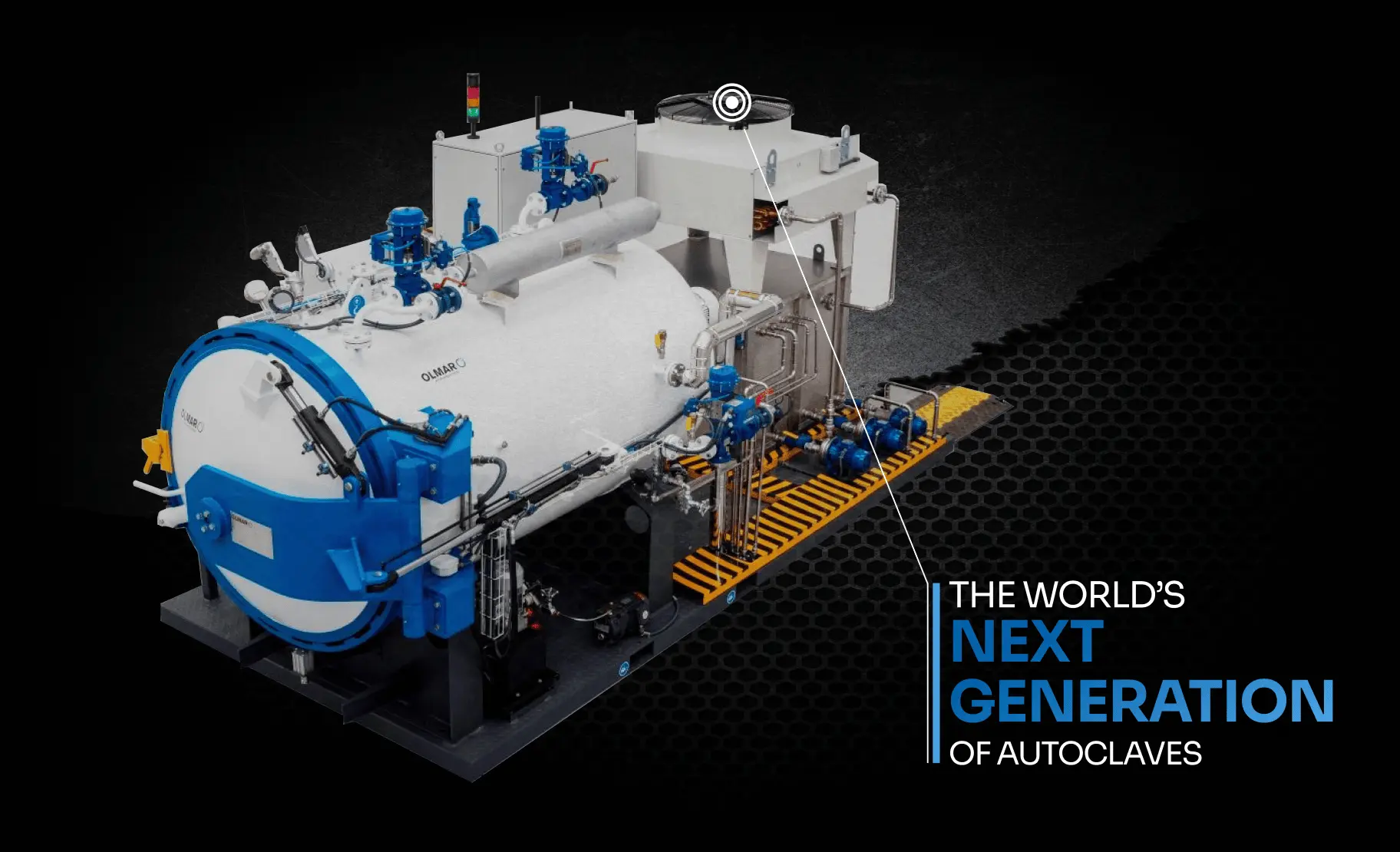

Olmar ATC composite autoclaves are considered to be the most advanced pieces of equipment in technical and design terms, as they are used in the sectors with the highest investment in research and development of new materials, such as aeronautics and aerospace engineering.

- Industries

- Other Autoclaves

Technical characteristics

We manufacture fully bespoke composite autoclaves, providing our customers with the highest quality and ensuring maximum performance in each cycle of its useful life.

Pressure

0 - 70 BARG

TEMPERATURE

0 – 450ºC

DIAMETER

500 mm – 9.000 mm

LENGTH

500 mm – 70.000 mm

SECTORS

Aeronautics, aerospace, automotive, racing, sailing, etc.

Heating system

Electrical resistors / Thermal oil / Steam

Pressurisation system

Air / Nitrogen

Additional technical features, available

on request

The emergence of these new materials has brought about huge progress in many of these sectors: the aeronautics industry (with the new A380 / A350), Formula 1, the aerospace sector (rockets, satellites), sports equipment (skiing equipment, surfboards), construction (shells, structural beams), etc. All of them have started to use composite components such as glass fibres, aramids, polyamides, polymers and special plastics.

Composites are consolidated by means of cycles for heating and cooling them at a given pressure, with variable parameters depending on their composition and the characteristics required for each process. Olmar’s new OCS software makes it possible to control, study and take action on all of the variables of the process in real time, ensuring optimum results for each cycle.

Thanks to this control system, which was fully developed by the company’s electrical and software departments, Olmar is able to offer its customers optimised performance and, through its innovative reporting technology, the most accurate control and data analysis system on the international market, making a firm commitment to developing the so-called ‘Industry 4.0’ and applying all of the innovative features available in its autoclaves.

ATC Compact Plant

Put your trust in us

/ Composites /

Everything you need to know

Composite materials (also called “composites”) have become a sought-after technological and industrial solution worldwide, both for large companies and small manufacturers. Composites can be used in a wide range of industrial projects and processes, and are increasingly replacing common materials such as steel and aluminium, given the enormous benefits of using them in very diverse fields. Since it started its activity in this sector, Olmar has dedicated a large part of its resources and R&D to researching the possibilities of these new materials, and has become a national and international benchmark in their study and industrial application.

- High level of technological development

- Greater level of efficiency during its entire life cycle

- Large amount of investment in innovation a research

- Reliability and durability: thereby ensuring the best performance

- Constant improvement in performance

Precision and reliability are key factors in the composite parts manufacturing process. All of the processes that take place inside the autoclave must be closely monitored and controlled due to the high standards that these parts have to meet before being installed as a finished product.

In this sense, Olmar has developed the most advanced software in the world for autoclaves for processing carbon fibre, thereby fulfilling its objectives of digitalisation and efficiency in manufacturing processes.

Its OCS control software integrates all of these features, thereby reducing the autoclave’s consumption costs, improving its productivity and optimising any periodic maintenance tasks that need to be carried out. Our technical service provides first class support in any country in the world, thanks to its high degree of connectivity and the incorporation of the most advanced remote connection solutions.

OLMAR carbon fibre autoclaves are, in short, intelligent autoclaves capable of automatically controlling the pressurisation with air or nitrogen, the heating ramp rates of these fluids using electric batteries or high-performance thermal oil, the maintenance of vacuum, pressure and temperature values (thermocouples) during curing, and the subsequent cooling and depressurisation of the autoclaves and ovens for carbon fibre processing, thereby making it possible to control and configure each of their phases.

It is not only important to monitor and analyse these values (pressure, vacuum and temperature) during the cycle, but also after the cycle. It is possible to identify potential areas for improvement and optimise the cycle as far as possible by studying all the data collected during the process.

Olmar has focused its efforts on creating an “intelligent” composite autoclave, concentrating its efforts in the fields of energy efficiency, usability, predictive control and low maintenance.

All of this has been embraced by Olmar, a solid business structure, with a family tradition, yet at the same time flexible and agile, capable of carrying out the entire manufacturing process “in house” to minimise outsourcing; a company focused on a continuous search for innovation and growth, as demonstrated by its latest business line: “Olmar Additive Manufacturing”, a cold metal additive technology with a revolutionary concept stemming from our investment in R&D.

Olmar’s experience, backed by thousands of international references and top tier customers, has grown over the years based on values such as excellence, effort and constant innovation. Leading companies such as Airbus Defense & Space, Airbus Helicopters, General Electric Aviation, Comac, Fokker GKN and many others have put their trust in Olmar autoclaves to undertake some of their most important projects, in programmes that provide the most innovative solutions in sectors such as aeronautics and aerospace. Proof of this is the large number of programmes in which Olmar’s autoclaves and control systems are used and have been integrated; from the manufacture of small carbon fibre surfboards and paddle rackets to the complex manufacturing and assembly processes of the new A350XWB, A320 NEO, A400 M, Airbus A380, COMAC’s 929 model and sections of Boeing’s 737, 777 and 787, among many others. With applications as varied as the development of space shuttles for the Ariane 6 (European Space Agency (ESA) project), some of the components for the top F1 teams and the fastest car in the world made by Koenigsegg, and even new forms of passenger transport such as the so-called ‘electric flying taxis’; Olmar has been involved in all of them, actively contributing to current, disruptive projects that will change our future, providing effort, excellence and innovation in technological solutions for autoclaves for curing composites that have never been seen before. Our control software, which is currently considered to be the most advanced application for curing composites, has made Olmar a point of reference internationally in an increasingly competitive world market.

Aeronautics is perhaps the most visible field of application of these new technologies. At the end of the 20th century, the use of aircraft as a means of transport began to spread around the world, but since the start of the 21st century, the growth of commercial aviation has been exponential. Far from being the luxury of yesteryear, the use of air travel as a regular means of transport has become widespread in almost every country in the world, from Europe to Asia, the Americas, Africa and Oceania. This “democratisation” of commercial aviation as a mainstream means of transport requires an unprecedented response in the global aviation industry: in 2015 there were more than 3 billion passengers and by 2050 the figure is estimated to reach 6 billion. In terms of the number of flights, the average number of flights per day at the end of 2015 was 102,000, but more than 300,000 flights per day will be needed to meet demand in 2050. If the world’s population is 7.4 billion now, and is estimated to be 9.7 billion by 2050, the changes, infrastructure and technological advances to meet that demand will be in the realm of “science fiction”. The use of composites will play a key role in meeting this challenge, as ever lighter, more efficient and better performing aircraft will be required to serve an ever-increasing number of passengers.

In this promising scenario of growth and new challenges, Olmar has consolidated its position as a world leader, presenting its equipment and technological solutions as a guarantee of the highest quality and efficiency when it comes to tackling the industry’s challenges in the coming years. Thanks to the experience acquired over its 75-year history and a team of highly qualified technicians and experts, the company is looking to tackle these new challenges with the security and confidence necessary to respond to the needs of its customers all over the world.