/ Tooling /

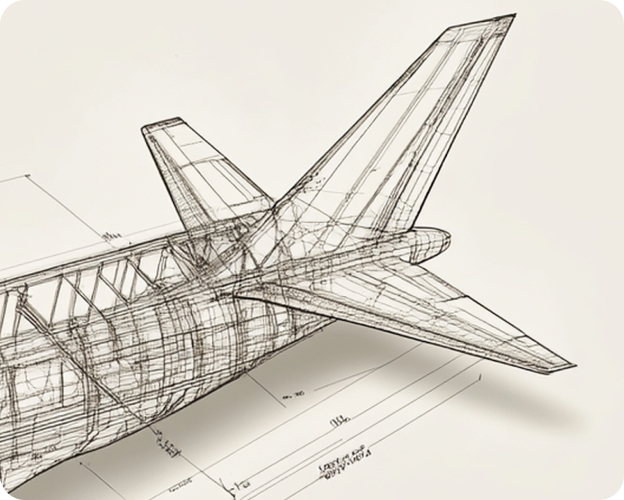

Autoclaves & Additive Manufacturing

Founded in 1945 and now a world leader in manufacturing autoclaves for curing composite materials, OLMAR has launched its new Additive Technology division

After more than three years of investing in R&D and incorporating the most advanced technologies into its state-of-the-art plant, OLMAR | Autoclaves & Additive Manufacturing was created with the goal and capacity to take on the most demanding challenges:

- Additive Technology

Capabilities of cold spraying

- The process is carried out at a relatively low temperature, which prevents impurities from metal oxides and other limitations found in traditional thermal spraying processes.

- The sprayed materials have very low porosity levels (<1%), as the process is carried out with the material in a solid state.

- The sprayed metals are very tough, due to the impact hardening of the material during the process.

- The initial composition and structure of the sprayed metals is preserved due to the low operating temperature, which means that the chemical composition, phase composition and crystal (grain) of the solid spray particles undergo minimal heating.

- Coatings of all types of materials with no compressive residual stress, which means that the material can be deposited in almost any thickness required.

Advantages of cold spraying

- Minimal heat input to the substrate

- High joint strength

- Compressive residual stresses

- Very thick coatings

- No phase changes

- No oxidation/rusting

- No grain growth

- High conductivity

- High resistance to corrosion

- Very tough and hard

Related news

A gateway to innovation in composites Autoclaves play a central role in the development and..

Olmar will showcase its latest innovations in autoclave technology and advanced industrial ovens at booth..

Three state-of-the-art compact autoclaves manufactured by Olmar are taking center stage in aerospace innovation programs..